Reducing Factory Waste

Over the years Scanpan has worked closely with our recycling partners to find as many sources to recycle factory, office, and production waste as possible. Though there are some manufacturing materials that cannot be recycled in any way, our goal is to keep these to a minimum and recycle or repurpose as much as we possibly can. As a result of our dedication to this goal, materials that could only be thrown in a landfill in the past are now able to be recycled in new and innovative ways.

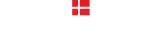

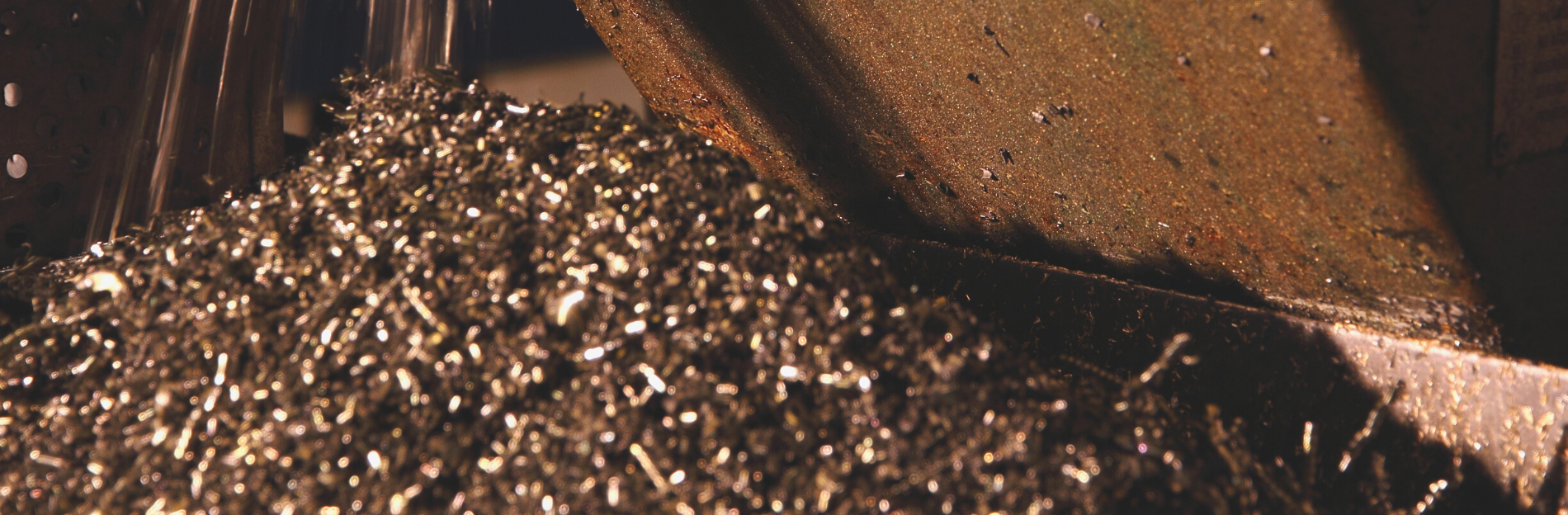

For example, during cookware processing we use a mineral called corundum to sandblast pans before our nonstick is applied. After sandblasting, leftover corundum (which is smaller and rounder than what we purchase) is filtered and returned to our supplier to be cleaned and re-sold to other industries who are in need of rounder particles to ensure it does not go to waste. When waste from production cannot be recycled, that which is safe to be incinerated gets burned and used to heat cities around our factory, which reduces the use of gas, coal, and oil. As of 2022, only 9% of our total company waste went into a landfill.

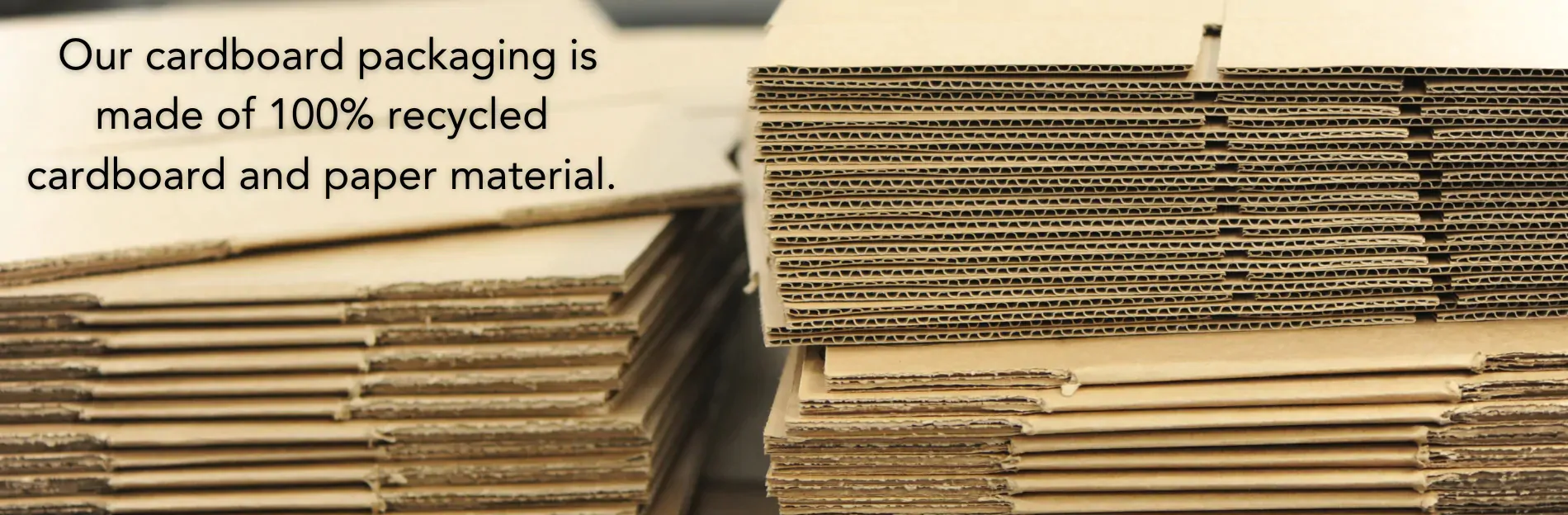

Eco-friendly Packaging

At the product level we also aim to keep waste as minimal as possible. Our cardboard packaging is made of 100% recycled cardboard and paper material, and we keep our packaging and packaging inserts minimal to reduce waste. Our insert printing company bears the Nordic swan label, which means they have met high standards of environmental, quality, and health in their production. Finally, all packaging is also of course 100% recyclable, keeping the cycle going.

Not every piece of packaging is perfect yet, though. Our pans are currently packaged with a plastic sleeve to protect the pans in transit. Though there are many alternatives to conventional plastic these days, we have found that the manufacturing and production of many of these alternatives creates substantially more pollution than conventional plastic manufacturing, making a switch to one of these “greener” alternatives less than optimal. We are continuing to pursue other options beyond a traditional plastic insert and hope to make a change to this component soon, but for now we believe this remains the best option available for the environment as a whole.